Lead glass, X-ray panels, and radiological windows — essential protection against radiation!

Lead glass, lead panels, and X-ray windows are essential components of radiological protection used across various industries. With their ability to effectively block X-rays and gamma radiation while maintaining high transparency, they are widely applied in construction, industry, and other fields requiring protection against ionizing radiation.

In construction, lead panels are an indispensable element in buildings requiring radiological protection. They can be installed in specialized windows that ensure radiological sealing and comply with safety standards. Installation techniques and the use of appropriate frames make these panels highly effective in shielding against radiation while providing durability and functionality to the structure.

In industry, lead panels are widely used in industrial laboratories, such as pharmaceutical, chemical, and nuclear energy facilities. They also serve as protective components in X-ray inspection systems, enabling safe product quality control without exposing operators to radiation.

Other applications include airport infrastructure, where lead panels are used in security screening systems, providing protection against radiation in baggage scanners. In research facilities such as physics laboratories, lead glass plays a crucial role in working with radiation-emitting materials, enabling safe scientific research.

With their versatility and the ability to customize technical parameters, lead glass, X-ray panels, and radiological windows are indispensable components in environments requiring the highest level of radiological protection.

Available variants of x-ray lead glass

- Sheets with standard Pb protection levels.

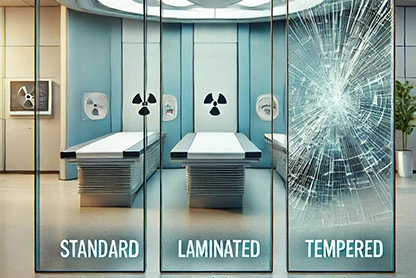

- Laminated glass or solid blocks: customized to any Pb level required by the user.

Available processing options for lead glass

- Laminated X-ray glass: e.g., combined with anti-reflective, fire-resistant, or float glass.

- Tempered X-ray glass: available with a protection level of 0.5 mmPb.

- Panels in various shapes: from round glass (e.g., porthole style) to custom shapes based on client drawings.

- Edge finishing: milling, polishing.

- Holes and cutouts: made according to client-provided drawings.

Applications of lead glass

- Protective windows in X-ray rooms, angiography labs, and CT scan facilities.

- Observation windows in X-ray shielding partitions.

- Glass used in protective barriers.

- Protection during NDT (Non-Destructive Testing) inspections.

- Protective glass in X-ray safety goggles.

Available maximum dimensions and weight of lead glass panels

Lead glass is offered in various thicknesses and protection levels, tailored to the individual needs of users. The maximum dimensions and weight of the panels depend on the glass thickness and the required level of protection. It is also possible to produce panels in smaller dimensions, making them suitable for more compact spaces or custom projects.

Maximum dimensions and weight based on glass thickness:

- 6.0 mm thickness – protection level of 0.5 mmPb, dimensions up to 1500 × 2350 mm, weight 20.0 kg/m².

- 4.0–5.5 mm thickness – protection level of 1.2 mmPb, dimensions up to 1000 × 2000 mm, weight 26.4 kg/m².

- 5.0–6.5 mm thickness – protection level of 1.5 mmPb, dimensions up to 1200 × 2400 mm, weight 31.2 kg/m².

- 7.0–8.5 mm thickness – protection level of 2.1 mmPb, dimensions up to 1370 × 2740 mm, weight 40.8 kg/m².

- 8.5–10.0 mm thickness – protection level of 2.6 mmPb, dimensions up to 1300 × 2600 mm, weight 48.0 kg/m².

- 10.0–12.0 mm thickness – protection level of 2.9 mmPb, dimensions up to 1000 × 2000 mm, weight 57.6 kg/m².

- 11.0–13.0 mm thickness – protection level of 3.2 mmPb, dimensions up to 1300 × 2600 mm, weight 62.4 kg/m².

- 12.0–14.0 mm thickness – protection level of 3.5 mmPb, dimensions up to 1200 × 2700 mm, weight 67.2 kg/m².

- 14.0–16.0 mm thickness – protection level of 4.1 mmPb, dimensions up to 1000 × 2000 mm, weight 76.8 kg/m².

- 16.0–18.0 mm thickness – protection level of 4.7 mmPb, dimensions up to 1000 × 2000 mm, weight 86.4 kg/m².

- 18.0–20.0 mm thickness – protection level of 5.2 mmPb, dimensions up to 1000 × 2000 mm, weight 96.0 kg/m².

Smaller panel dimensions

In addition to standard maximum dimensions, panels can also be produced in smaller sizes, making lead glass an excellent choice for use in confined spaces or specialized projects, such as custom windows or protective barriers.

Higher protection levels

For projects requiring greater radiological protection, laminated glass is available, offering Pb levels higher than standard values. These solutions are custom-made and tailored to the specific requirements of the user.

Required information for order fulfillment

To produce lead glass, lead panels, or X-ray windows, the following details must be provided:

- Dimensions of the installation opening: width and height of the opening where the glass or window will be installed.

- Wall thickness: necessary to adjust the frame and determine the installation method.

- Lead glass thickness and protection level (mmPb): selected according to the required level of protection.

- Type of frame: material and type (e.g., aluminum, steel) along with the installation method.

- Additional requirements: holes, cutouts, seals, or non-standard formats as specified in the customer’s design.